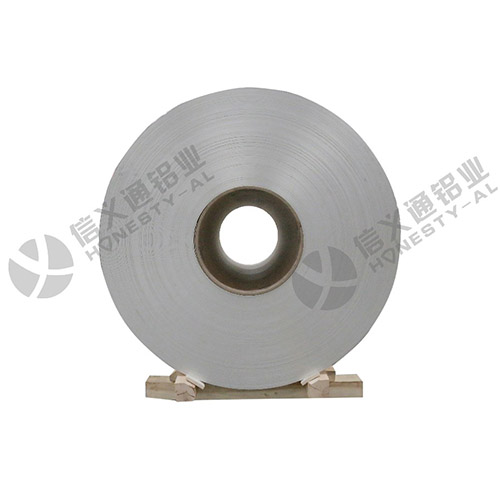

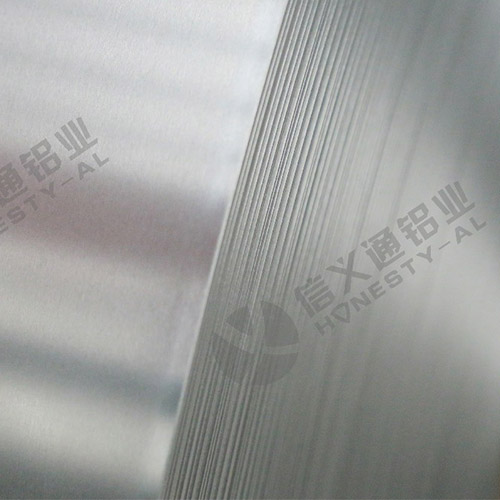

The main alloying element of 7050 aluminum is zinc. Adding magnesium to the alloy containing 3%-75% zinc can form MgZn2 with a significant strengthening effect, so that the heat treatment effect of the alloy is far better than that of the aluminum-zinc binary alloy. It is used for aircraft manufacturing structures and other high-stress structures that require high strength and strong corrosion resistance.

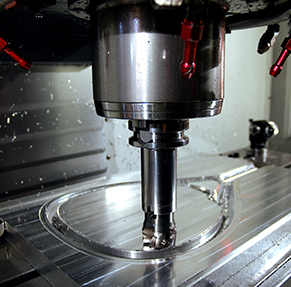

7050 aluminum is often used in aerospace, mold processing, mechanical equipment, tooling and fixtures; especially for aircraft manufacturing structures and other high-stress structures that require high strength and strong corrosion resistance.